In 2026, Amandus Kahl will celebrate its 150th anniversary under the motto “150 Years of Innovation – Tradition with a Future”. From Hamburg, Germany, to the world: Amandus Kahl has shaped global mechanical and plant engineering, and is currently one of the world's leading manufacturers of pellet mills, process engineering, and complete production plants for the feed, biomass, recycling, food, chemical, and pharmaceutical industries.

Amandus Kahl started in Hamburg in 1876 under the name Wendte & Kahl, initially focusing on stoves and ovens.

The acquisition of an iron foundry in the nearby town of Stade marked the beginning of in-house production, forming the basis for the company’s later specialization in mill and plant construction.

For decades, the company operated in both locations simultaneously. Sales, design, and development were based in Hamburg, while production took place in Stade and, later, Hamburg.

Move to Reinbek

The company’s focus has always been on innovation, quality, and long-term sustainability; however, in 1965, the most significant structural change in the company’s history occurred.

The move to Reinbek brought together the administration, engineering, design, and production departments at a single location for the first time.

This laid the foundation for the factory that stands there today. Since then, the site has undergone continuous expansion and modernization, including investments in new production capacities and expansion of the machine park.

Covering approximately five hectares, the site now forms the center of the KAHL Group and will continue to be an important location for its future development.

A full-service provider with a broad portfolio

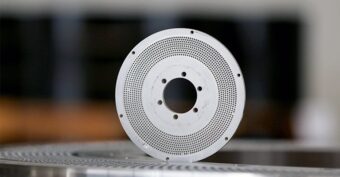

Amandus Kahl gained international recognition primarily through the development of the flat-die pellet mill, which exemplifies the company’s ability to combine tradition with technical innovation.

First developed in the mid-1920s, the pellet mill remains the company’s core product to this day and will continue to do so in the future.

Over the past few decades, it has been consistently adapted to meet the demands of a variety of applications, including throughput rates and specific product properties.

This makes the KAHL flat-die pellet mill suitable for many industrial processes, including feed and biomass processing, recycling, and food, chemical, and pharmaceutical applications.

Alongside pellet mills, Amandus Kahl’s portfolio now encompasses expanders, extruders, pan grinder mills, crushing roller mills, driers, coolers, and fluidized bed plants.

Over the years, the portfolio expanded to include both individual machines and turnkey production lines.

Global engineering group

Amandus Kahl is the flagship company of the KAHL Group, which comprises nine market leaders in their respective industries, employing around 900 people in total.

This merger, which has evolved, began with the acquisition of Neuhaus Neotec in 1990 and brings together expertise in areas ranging from process engineering to plant construction.

The company’s own pilot plant plays a particularly important role in testing raw material properties, developing formulations, and defining process parameters for industrial applications. This provides customers with reliable results for designing new plants and products.

Our anniversary is an opportunity to reflect proudly on the developments of the past 150 years and, at the same time, set the course for the future. Innovation arises where experience and curiosity come together. This interplay between tradition and the future has shaped our company for generations and will remain a central component of our corporate culture, said Dr Joachim Behrmann, Amandus Kahl’s Managing Director.