In Germany, ETW Energietechnik GmbH, a full-service provider of biomethane aka renewable natural gas (RNG) plants and combined heat and power (CHP) plants, has announced that it has been awarded a contract by Berliner Stadtreinigung (BSR) for a facility that will process up to 700 Nm³/h of landfill gas (LFG) into biomethane.

The plant concept was developed and planned by BSR in close cooperation with the planning office Rytec GmbH.

Rytec brings extensive expertise in biogas production, biological and thermal waste treatment, energy technology, and waste and landfill technology to the project.

With the ETW treatment process specially developed for landfill gas with a downstream nitrogen reduction unit (NRU), landfill gas with nitrogen contents of over 22 per cent can be converted into biomethane suitable for feed-in. Following the consistently positive operating experience of our first reference plant in Taranto, Italy, which has been running successfully for over a year, this new contract confirms the market’s confidence in our engineering expertise and plant technology, explained Alexander Szabo, Sales Manager at ETW Energietechnik.

Fluctuations in gas composition and quantity

Landfill gas (LFG) is a special gas for processing. On the one hand, it has a very high concentration of trace pollutants – volatile organic compounds (VOCs) and siloxanes.

On the other hand, the gas quality is not constant. This results in fluctuations in gas composition and gas volume.

The longer a landfill site is in operation, the more methane is replaced by oxygen and nitrogen. In addition, the overall gas volume decreases over time.

High demands on gas processing

These factors place very high demands on a biomethane plant for gas processing. The methane concentration is between 35 and 60 percent, and the nitrogen and oxygen concentration is up to 23 percent.

At the same time, the operating range or partial load capacity is between 40 and 100 percent of the plant capacity.

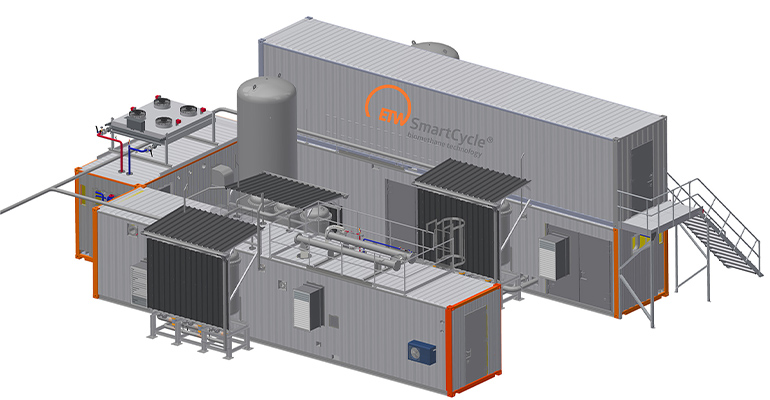

To minimise the external electricity requirements of the biomethane plant, ETW is also supplying a combined heat and power (CHP) unit for its own electricity supply, which is also operated with the off-gas from the processing plant.

According to ETW Energietechnik, this increases the methane yield of the entire plant to over 95 percent. The value of the contract with BSR has not been disclosed.