Sweden-headed steelmakers SSAB has published a plan that involves a "drastic cut" in carbon dioxide (CO2) emissions even before a solution for fossil-free steel has been found. The goal is to be totally fossil-free by 2045. The transition in SSAB’s business is a consequence of the SSAB, LKAB and Vattenfall initiative to find a solution for fossil-free steel production, HYBRIT.

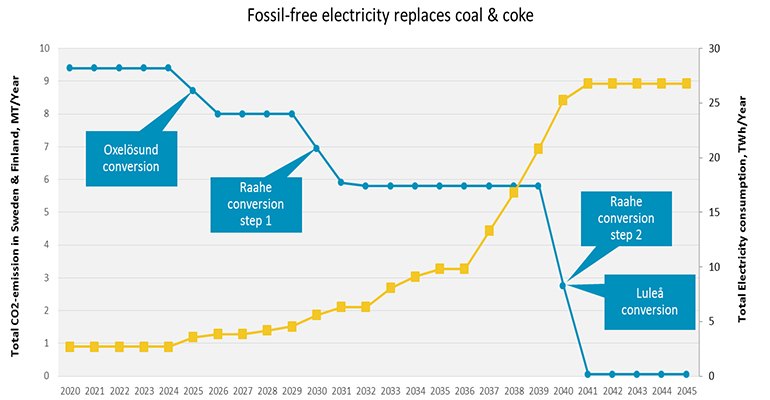

According to a statement, a study is currently underway to convert the blast furnace in Oxelösund, Sweden into an electric arc furnace. This is the first step in adapting the process for the production of fossil-free steel. The conversion will take place in around 2025 and would mean that SSAB can cut its carbon dioxide (CO2) emissions in Sweden by around 25 percent.

The company has also announced that it is planning to convert the blast furnaces in Raahe, Finland and Luleå, Sweden between 2030-2040 in order to eliminate most of the remaining CO2 emissions and reach the target to be fossil-free by 2045.

The transition to fossil-free steel production has already started, and we’re now detailing what the road ahead will be like. We believe that this is the right way to go and that it will create many exciting business opportunities for us as a company. SSAB wants to be part of the solution to climate change, said Martin Lindqvist, President and CEO of SSAB.

The transition in SSAB’s business is an outcome of SSAB’s, LKAB’s and Vattenfall’s joint initiative to find a solution for fossil-free steel production, HYBRIT. Currently, the coal and coke used to reduce iron ore into iron are shipped to Sweden from places including Australia, a process that gives rise to large volumes of fossil CO2 emissions.

The idea behind HYBRIT is to use hydrogen, produced with electricity from “fossil-free” sources, in the steel making process which gives rise to water instead of CO2. According to SSAB, Sweden and Finland have a “unique opportunity” to drive an initiative for fossil-free steel, with good access to climate-smart and fossil-free electrical power, Europe’s highest-quality iron ore and a specialized, innovative steel industry.

The company notes that to complete this project, significant national contributions are still required from the state, research institutions, and universities.

Facts

About SSAB

SSAB is a highly-specialized global steel company and a leading producer on the global market for Advanced High-Strength Steels (AHSS) and Quenched & Tempered Steels (Q&T), strip, plate and tubular products, as well as construction solutions. SSAB’s production plants in Sweden, Finland and the US have an annual steel production capacity of 8.8 million tonnes. The company also has capacity to process and finish various steel products in China, Brazil and many other countries. In Sweden and Finland, production is integrated into a blast furnace process. In the US, electric arc furnaces are used for a scrap-based production process.