Sweden’s PetroBio is a household name in the Nordic district heating- and industrial process heat circles, known for its bespoke multi-fuel burner technologies for industrial applications. In essence, Sweden’s district heating development and fuel transition – from fossil oil and gas to biofuels, biogas, and solid biomass – is mirrored in the company’s six-decade timeline, as Bioenergy International discovers on a trip to Gothenburg, and the “doll-house” in Alingsås.

A family-held company based in Gothenburg, and a VYNCKE Group company since 2018, the company currently has a portfolio of four core burner technologies each with multi-fuel options for solid, liquid, or gaseous fuels for industrial applications in the 2-50 MW range.

The scope of supply ranges from replacement and retrofit ope-rations to boiler plant rebuilds or new boiler plants complete with combustion units, fuel preparation systems, boilers, and flue gas treatment.

Each project is unique with its set of parameters, conditions, and constraints. Our job is to design and engineer the most optimum technical and economical solution for the client including after-sales service and support given those specific circumstances. Whatever the solution, it must be robust yet easy to operate and maintain, explained Daniel Persson, Senior Sales Manager who has been with PetroBio for 30 plus years.

A powerful duo

PetroBio was founded in 1964 as Petrokraft by the Larsson brothers. In fact, two companies were formed by the brothers: Petrokraft to design the burners, and FerroTeknik, an engineering and manufacturing workshop to fabricate them.

The two companies have followed each other as close partners and FerroTeknik continues to manufacture PetroBio’s burners from its original location in Floda just outside Gothenburg, while PetroBio has a stockholding of spares and wear items nearby in Floda.

Firing liquid- and gaseous fuels is where the PetroBio story started. The founding coincided with the development and build-out of the district heating network throughout Sweden during the 60’s and 70’s, explained Daniel Persson.

In 1969, Sten A. Olsson, founder of the global shipping, offshore, recycling, and real estate group STENA, acquired Petrokraft via his oil-fired boiler company Generator.

Generator oil boilers with Petrokraft burners became synonymous with heat plants during the 1970s and 1980s as district heating continued to grow.

The Generator boiler business was subsequently divested but Petrokraft was kept in the STENA family, and remained so for three generations, until 2018, when VYNCKE acquired PetroBio.

The first projects

The very first project listed in PetroBio’s archive is the delivery of a 3 MW low-pressure air atomizing burner in 1964 to a dairy in northern Sweden, which up until 2005 was still ordering spare parts for that burner.

1969 saw the first export project – a 5 MW low-pressure air atomizing burner to Finland, and the same year Petrokraft supplied a 9 MW oil burner to Lithells meat processing plant in Sköllersta.

In 2014, PetroBio was tasked to build a new wood powder-fired steam boiler plant for Lithells (now Atria) in Sköllersta complete with a pellet silo, milling, power burner, steam boiler, and flue gas treatment to replace the old oil-fired system.

The development of the rotary cup burner enabled new emission reduction possibilities for flame combustion and 1974 saw the first delivery of these burners to Sala-Heby Energi’s Silververket combined heat and power (CHP) plant in Sala.

The burners are still operational and Silververket has had fossil-free energy production since 2000.

The rotary cup burner has of course been further developed over the years and is still very much a relevant solution today. Most of the conversions from fossil oil to bio-oil of the old Generator-Petrokraft installations from the 60s, 70s, and 80s use rotary cup burners, remarked Daniel Persson.

Marine applications

A little-known curiosity that accounts for a tangible share on the revenue pie chart is that PetroBio burners have sailed the Seven Seas, been to the North Pole, and as close to the South Pole as one can get on a boat.

And yet despite connections to STENA, not on a STENA vessel one might add.

In 1980 we started collaboration with Sun-flame, a Japanese company that supplies auxiliary steam systems for onboard heat and power. To date, we have delivered over 800 burners installed on various types of vessels around the world ranging from oil tankers to cruise ships and ice breakers. Just recently the Swedish ice-breaker Oden updated its burner control system so we were kindly given the “Petro-Pilot” consul as a keepsake, said Johanna Lindén, CEO of PetroBio who has been with the company for almost a decade.

Prior to joining PetroBio, she had a long career with Valmet in Gothenburg. Moreover, Johanna Lindén also serves on the board of the Swedish Bioenergy Association (Svebio).

Carbon tax and powder power

Already in 1987, PetroBio delivered its very first commercial wood powder combustion project to Hallstahammar, although the plant has since been decommissioned.

In 1993, Söderhamn Energi took delivery of its very first PetroBio wood powder installation and upgraded it in 2016. Still operational, it is with its thirty years the oldest operating PetroBio wood powder installation.

The 1990s saw the introduction of the carbon tax in Sweden, and that is really when the interest in renewable fuels, in particular bio-oils for district heat and process heat, began to take off. We could match that interest with our portfolio of low-pressure air atomizing- and rotary cup burner solutions, and the wood powder concept. The end of the millennium perhaps marked the beginning of our migration from being a burner technology provider to being even more customer-centric with project design, engineering, and (re) building entire plants, said Johanna Lindén.

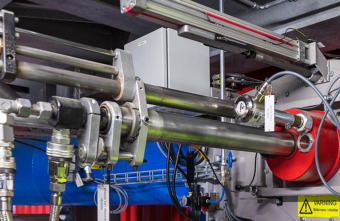

In the early 2000s the fourth burner type was introduced, a retractable auxiliary burner lance typically used for boiler start-ups or temperature maintenance in waste-to-energy (WtE) boilers.

The latter is a critical function to ensure compliance with the EU Waste Incineration Directive (WID) that the temperature of the combustion gases after the injection of final combustion air remains above 850 oC to avoid the formation of pollutants such as dioxins.

The auxiliary burner lance is fully automated and retractable which is an advantage in challenging combustion environments as it is not used continuously. Most deliveries of the burner lance are based on bio-oils as a means to reduce the carbon footprint of the fuel mix at waste-to-energy facilities, Johanna Lindén said, the Värmevärden (now Adven) RDF-fired plant in Säffle a case in point .

Inside the “doll’s house”

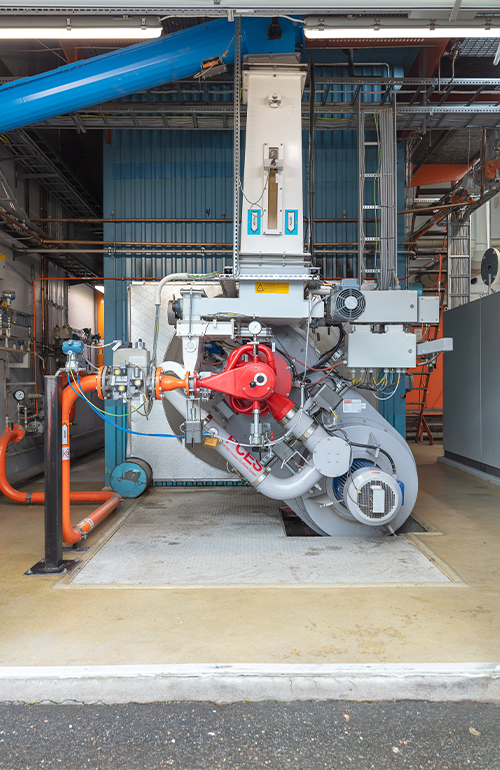

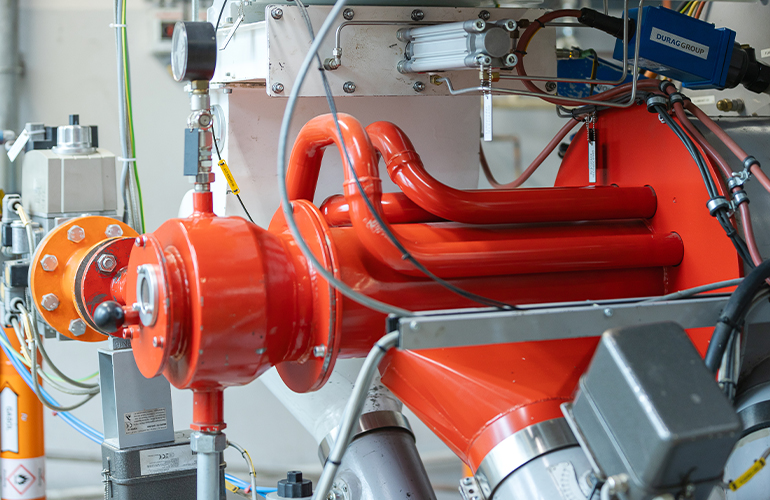

A classic PetroBio installation is found at an industrial laundry in Alingsås, about 30 km from the PetroBio headquarters.

Fondly known as the “doll’s house” as it is both pedagogical and easy to follow from fuel to flue, it is a prime example of a retrofitted Generator-Petrokraft steam boiler installation proving that even old boilers can be given a new lease of life and still be in compliance with strict environmental regulations.

Originally installed in the 1970s as a classic oil-fired Generator-Petrokraft delivery, the boiler was subsequently retrofitted to run on liquefied petroleum gas (LPG) as the main fuel with oil as the backup.

In 2013, the same boiler was retrofitted yet again, this time to run on pulverized wood pellets as the main fuel with LPG as the backup.

At full load, the 6.5 MWth steam boiler generates up to 4.5 tonnes per hour of steam at 16 bar.

The steam is used for the laundry’s heating and drying process. A key feature is the volatile load demand which places a rapid turn-down ramp-up response capability on the burner and boiler.

The scope of supply for PetroBio included a pellet silo, milling unit including a housing, powder dosing system, wood powder/LPG burner, modification of the boiler-burner connection to accommodate a longer flame, post-combustion flue gas treatment to remove fly ash and any unburnt particles.

As you can see, the “doll’s house” is a perfect showcase of a wood powder installation for us. Thanks to the kind willingness and cooperation of the laundry, we’ve brought countless visitors here since 2013. They’ve come from all over the world and from all kinds of companies, research organizations, local authorities, and even conference delegates, and new employees, Johanna Lindén said.

Petrokraft to PetroBio

Back in 1964, the name ”Petrokraft” said it all, quite literally “Petro(leum) Power”. It was only a decade ago, in 2014, that Petrokraft changed its name to PetroBio to lessen the emphasis on fossil fuels and better reflect the business toward renewable fuel solutions.

It may seem a paradox that “Petro” is still in the name but it has such a strong association with us as a company for many of our clients that we couldn’t drop it. PetroBio is perfect as it tells where we came from and where we are headed as a business. It also reflects the inherent multi-fuel capabilities that our burners have. We are proud of our heritage to have played a part in the development and expansion of Sweden’s energy system just as we take pride in assisting companies in the transition of that same system to renewable alternatives going forward, ended Johanna Lindén.

There is a lot to be proud of.

Over the last five years, PetroBio has supplied biobased energy solutions to defossilize a diverse range of industries and utilities where heat or steam is needed – pulp- and paper mills, wood processing plants, waste-to-energy plants, meat processing facilities, breweries, distilleries, laundries, confectionery manufacturers, furniture manufactures, asphalt plants, and laboratories.

Not just in Sweden but around the world as over ten of these projects have been supplied in partnership with VYNCKE. And more are to follow.