In Sweden, a ground breaking ceremony was held on June 20 in Luleå marking the construction for HYBRIT (Hydrogen Breakthrough Ironmaking Technology), a SEK 1.4 billion (≈ EUR 136.3 million) joint initiative of mining and ore producer LKAB, steelmaker SSAB and energy major Vattenfall along with the Swedish Energy Agency. Initiated in 2016, HYBRIT aims the design the world's first fossil-free ore-based steel production solution.

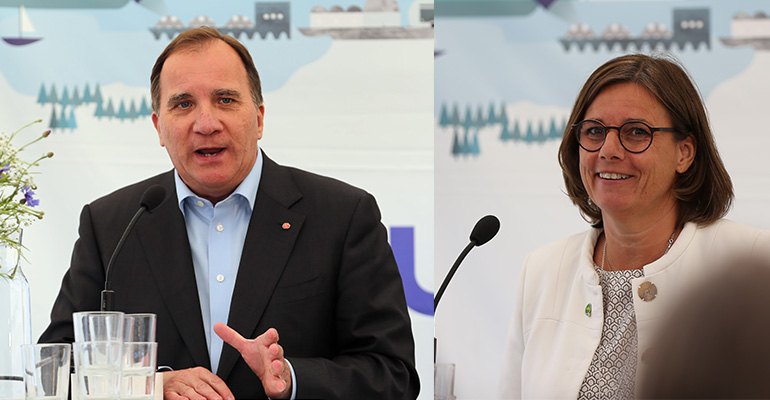

To be built at SSAB’s steel mill in Luleå, the ground breaking ceremony was jointly officiated by the Swedish Prime Minister Stefan Löfven and Deputy Prime Minister and Minister for International Development Cooperation and Climate Isabella Lövin along with representatives from the three companies and the Swedish Energy Agency.

The pilot plant is expected to be completed by 2020. The initiative was given the go-ahead earlier this year to proceed from feasibility study to pilot plant.

According to Mårten Görnerup, CEO at HYBRIT, this could lead to a “historic shift” in production technique, with water as a by-product of steel manufacturing instead of fossil carbon dioxide (CO2) emissions. The reduction reactions that take place in conventional blast-furnace that uses coke and coal or in a direct reduction fossil gas-fired ironmaking process represent around 85 to 90 percent of CO2 emissions in the ore-based steelmaking value chain.

Of Nordic climate and competitive significance

Finland and Sweden both have significant mining, iron and steel industries and HYBRIT has the potential to reduce Finland’s total fossil CO2 emissions by around seven percent and Sweden’s by about 10 percent.

The pilot phase consists of two projects – the main project is the direct reduction of iron ore pellets using hydrogen (H2) gas and their subsequent melting in an electric arc furnace for steel production by develop a technique in which pure H2 gas, produced using “clean” electricity, is used as the reducing agent in the production of sponge iron from iron ore pellets.

The second project for which the ground looks into the development of a fossil-free heating technique for the sintering of iron ore pellets. The dual aim is to reduce emissions from existing pellet plants and to design a new pelletizing process.

The construction start also means that the HYBRIT initiative is now entering its second phase, with possibilities of full-scale testing and development of the technique to replace coal and coke in the iron and steel manufacturing process. The goal is to have an industrial process in place by 2035.

Moreover, HYBRIT has a global potential to reduce CO2 emissions. This historic technological shift has been described as crucial for Sweden to be able to achieve the goals set out in the Paris agreement. Something that both PM Löfven and Deputy PM Lövin remarked on during their address respectively.