The Swedish fossil-free steel industry initiative HYBRIT has announced that a pre-feasibility study is giving the go-ahead for the planning of a globally-unique pilot plant for fossil-free steel production in northern Sweden. Jointly carried out by iron ore and steel majors LKAB and SSAB together with energy utility major Vattenfall, the companies behind the HYBRIT initiative, the study includes calculations the potential in due course to be able to commercialise fossil-free steel production.

In 2016, LKAB, SSAB and Vattenfall launched “HYBRIT – the way to fossil-free steel”, an initiative seeking to solve the carbon dioxide (CO2) issue in the Swedish steel industry. In June 2017, the trio formed a joint-venture (JV) and received SEK 60 million (≈ EUR 6.1 million) Swedish Energy Agency funding towards a four-year research project including a pre-feasibility study up to the end of 2017.

It is with great pleasure that we can announce today that we are giving the green light to the initiative to proceed with the planning and designing of a pilot plant for fossil-free steel in Luleå and the iron ore deposits in Norrbotten. We hope to be able to break the ground already before the summer. This spring we’ll also start investigating the possibilities of broadening the project to include Finland. We are also very pleased that the Energy Agency wants to support us in this project, said Mårten Görnerup, CEO of HYBRIT.

Fossil-free steel will become cost competitive

The aim is to have a totally fossil-free process for steel production by 2035. The pre-feasibility study includes calculations and the potential in due course to be able to commercialize fossil-free steel. The conclusion is that fossil-free steel, given today’s price of electricity, coal and carbon dioxide (CO2) emissions, would be 20-30 percent more expensive.

However, the study also concludes that with declining prices in electricity from fossil-free sources and increasing costs for carbon dioxide emissions through the European Union Emissions Trading System (ETS), that fossil-free steel will in future be able to compete in the market with traditional steel.

Global first-of-its-kind pilot plant

This spring the planning and designing of the “globally-unique” pilot plant will be initiated. According to a statement, it is the “first time in a 1 000 years” that there is an opportunity for a technology shift. The cost is estimated to be SEK 20 million (≈ EUR 2 million) and it was recently confirmed that the Swedish Energy Agency will finance half of this, while the other half will be covered by LKAB, SSAB and Vattenfall through the HYBRIT initiative.

Coal and coke that is currently used to reduce iron ore into iron are imported to Sweden from as far as Australia. The idea behind HYBRIT is to use hydrogen, produced with electricity from “fossil-free” sources, in the steel making process which gives rise to water instead of CO2.

Fossil-free steel production starts in the mine, and we’re currently working intensively on how the next generation of pellet plants will be designed, as well as how a future electrified and more highly automated mine should be designed. HYBRIT is an important driving force for LKAB, said Jan Moström, President and CEO of LKAB.

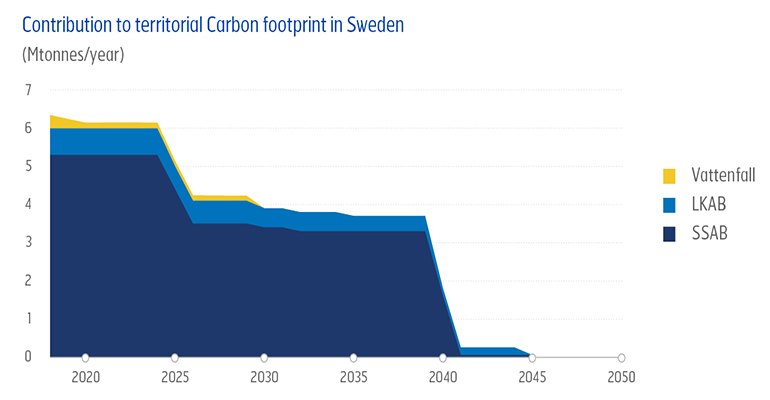

If successful, the pilot plant initiative could reduce Sweden’s total CO2 emissions by up to 10 percent and those in Finland by up to 7 percent. The reduction in Sweden has been described as being crucial if Sweden is to be able to meet the goals of the Paris Agreement.

Conversion to electric arc

Already before a solution for fossil-free steel making is in place, SSAB announced in a separate statement that it aims to cut its CO2 emissions in Sweden by 25 percent by as early as 2025, through conversion of its blast furnace to electric arc furnace in Oxelösund, Sweden.

HYBRIT is a significant part of the road towards SSAB’s goal of being fossil-free by 2045, and the report from the pre-feasibility study shows not only that is it possible to carry out this initiative, but it can also create exciting future opportunities for us as a company. We want to be part of the solution to climate change, said Martin Lindqvist, President and CEO of SSAB.

Between 2030-2040, the aim is to convert also the blast furnaces in Luleå, Sweden and Raahe, Finland to eliminate most of the remaining CO2emissions and to attain the target of being fossil-free by 2045.

Enabled by “fossil-free” electricity and hydrogen

It’s very positive that we can take the next step with a unique pilot plant, for both the project and for our work on the climate challenge. The industrial electrification and climate-smart hydrogen will be crucial factors in lower emissions and a fossil-free society, said Magnus Hall, President and CEO of Vattenfall.

Steel is a significant element of modern society, and according to SSAB, global demand for steel is expected to increase as the world’s population grows and urbanization increases. If a new process cannot be found for ore-based steel production, CO2 emissions from the steel industry will increase by up to 25 percent by 2050.

Furthermore, Sweden and Finland have a unique opportunity to drive an initiative for fossil-free steel, with good access to climate-smart and fossil-free electrical power, Europe’s highest-quality iron ore and a specialized, innovative steel industry.

However, the companies emphasise that significant national contributions are still required from the state, research institutions and universities to be able to carry out this project. This includes “good” access to “fossil-free” electricity, improved infrastructure and rapid expansion of high voltage networks, research initiatives, faster permit processes, active governmental support for pilot and demonstration facilities and long-term support at EU level.

With our commitment to the HYBRIT initiative, we are contributing to the long-term competitiveness of the Swedish steel industry and gearing up to work on the unique green energy systems in Sweden. In addition, we help in driving the transition to a fossil-free industry and a sustainable society, said Erik Brandsma, Director General at the Swedish Energy Agency.