France-headed multi-energy major TotalEnergies SE and Holcim (Belgique) SA, part of global construction materials and solutions major Holcim Group, have signed a Memorandum of Understanding (MoU) to work together on the full decarbonization of a cement production facility being upgraded by Holcim in Obourg, Belgium.

According to a statement, various energies and technologies will be assessed for the efficient capture, utilization, and sequestration (CCUS) of around 1.3 million tonnes of carbon dioxide (CO2) emitted by Holcim Belgium’s Obourg facility every year.

Cement industry decarbonization is extremely challenging because of the process’s inevitable CO2 emissions, which put us firmly in the hard-to-abate sector. CCUS is vital for Obourg to become the first net carbon-neutral clinker plant in northwest Europe, said Bart Daneels, CEO, of Holcim Belgium.

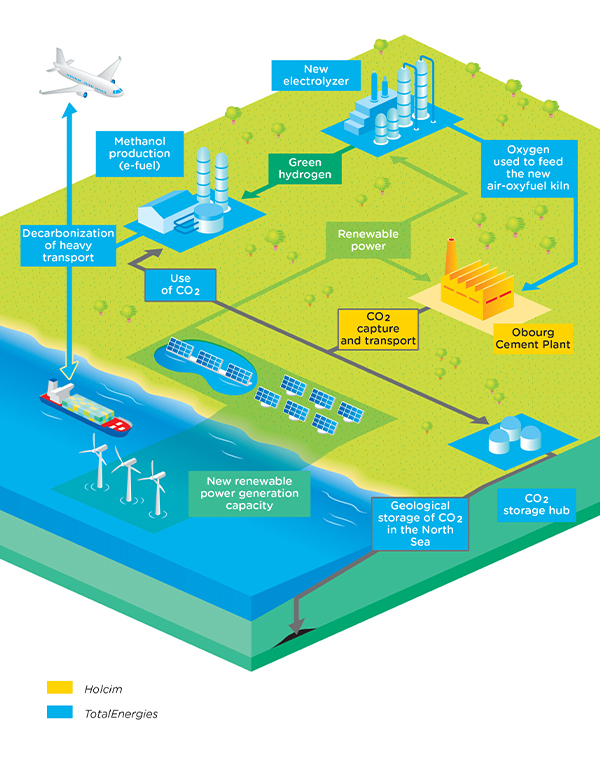

Each partner will contribute its best-in-class technologies and its know-how to explore and develop the project. This includes:

- an innovative new air-oxyfuel switchable kiln, to facilitate the capture and purification of CO2 in the flue gases, as part of Holcim’s upgrade of the current cement plant; and

- the transportation and use of the captured CO2 by TotalEnergies for an innovative e-fuel producing scheme and/or deposit in geological storage in the North Sea.

Integrated approach

TotalEnergies will assess the development of renewable projects to power a new electrolyzer, which would generate the green hydrogen needed to produce e-fuels.

The unique, integrated, and sustainable solution that we are looking to provide to Holcim for the full decarbonization of its cement plant emissions – with its range of technologies and new decarbonized molecules – is a first, marking a milestone in the decarbonization of heavy industry and its hard-to-abate emissions, said Christophe Sassolas, SVP, OneB2B Solutions at TotalEnergies.

This new renewable energy production capacity would also power Holcim’s new oxyfuel kiln, thus contributing to the decarbonization of the cement plant.

Finally, the oxygen emitted by the electrolyzer would be used to fuel the new kiln.

We are very happy to work with TotalEnergies to accelerate the development of these CCUS solutions for GO4ZERO. By joining the first movers, we want to set the standards for future clinker manufacturing plants, said Bart Daneels.

We are pleased to partner with Holcim to work on the development of sustainable and carbon-neutral industries in Europe, in partnership with our clients and in line with their decarbonization strategy. TotalEnergies is looking forward to deploying other integrated solutions like this one elsewhere, as we move toward reducing our scope 3 emissions, in line with our Climate Ambition to get to Net Zero emissions by 2050, together with society, ended Christophe Sassolas.